Silverson Machines: Revolutionary Food & Beverage Mixing Solutions

For more than 75 years, Silverson Machines has been a global leader in high shear mixing technology. In this time, we’ve helped hundreds of food and beverage manufacturers of all sizes to improve product quality, consistency and process efficiency.

At Silverson Machines, we understand that the mixing challenges of the food and beverage industry are unique and constantly changing. As well as being at the forefront of new applications and technologies, Silverson has a wealth of knowledge and experience to draw upon. From functional beverages to sauces to plant-based formulations and dairy alternatives, Silverson has partnered with manufacturers in over 150 countries to overcome their toughest mixing challenges. Trust our mixing experts to make sure you get the right mixer for application.

Sponsored by

Whether you’re concerned with reducing production times, sanitary processing, powder/liquid mixing, producing stable emulsions, dissolving, disintegrating solids, blending liquids of different viscosities, or dispersing and hydrating gums, thickeners, and stabilizers, Silverson has a mixing solution for you.

Silverson High Shear Mixers excel in:

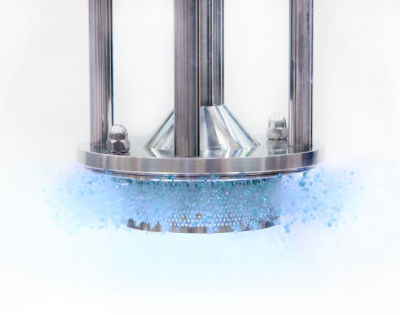

- Hydrating and deagglomerating gums and thickeners

For smooth, lump-free textures. Agglomerates are instantaneously broken down as they pass through the rotor/stator workhead, resulting in an agglomerate-free mix with maximum yield. - Reclaiming waste or out-of-spec product

To reduce losses and improve yield and subsequent batch quality. - Dissolving

For example, Silverson mixers can produce a 66 Brix sugar solution at ambient temperature. - Homogenizing

In many cases, a Silverson mixer can replace a high-pressure homogenizer in a processing line. They can also be used to create a uniform premix that will pass through a high-pressure homogenizer at a much faster rate and often in a single pass. - Reducing particle size

To improve mouthfeel and shelf stability. - High Viscosity mixing

The innovative pumping rotor design of some Silverson mixers allows them to process higher viscosity products. - Blending liquids of varying viscosities

- Forming stable emulsions

A Silverson mixer can easily create a stable emulsion with a droplet size of 2 – 5 microns, results down to 0.5 microns can be achieved depending on the formulation.

Scalable Results you can trust

We have a wide range of high-shear food mixers available that are ideal for food applications, ranging from our most popular L5M-A Laboratory mixer all the way up to in-tank mixers that can process batches of up to 8000 gallons. Silverson Machines offer the largest capacity range from a single manufacturer and part of our success – and that of our clients – is the accuracy with which we can predict the performance of our production scale mixers based on laboratory trials.

We see no point in using a laboratory mixer capable of speeds of 25,000 rpm or more if the results cannot be replicated in production. That’s why our laboratory mixers are designed and built to the same tolerances as our production units; comparable rotor tip speed and shear rates across our entire product line mean scalable results, every time.

Customization

As we design and build every Silverson mixer ourselves, unlike other equipment suppliers, this gives us the flexibility to custom design and build machines to meet our customer’s exact specifications and requirements. Whether you require a mixer to operate under ultra-sanitary conditions, high pressure or to be constructed in non-standard materials such as Hastelloy or Titanium, Silverson has the flexibility, knowledge, and capability to design and build a mixer to fit your exact requirements.

Try before you buy

Want to see what high shear mixing can do for your product?

Whether you are looking to improve your existing process or want to take advantage of the latest mixing technology in the development of a new product or process, see firsthand how Silverson mixers can benefit you. Prior to purchasing Silverson offers extensive testing either at our testing centers or at our customers’ own facilities.

We are confident that we can revolutionize your process – improving product quality and consistency and dramatically cutting mixing times – so we challenge you to put us to the test. A local Technical Representative can visit you and conduct laboratory scale trials on your product or for pilot and production scale applications our trial program allows you to conveniently test a larger mixer at your own facility.

Alternatively, you can visit one of our fully equipped Test Centers. These are available for the use of all clients and allow you to discuss your application with our experienced in-house technical staff and carry out your testing program. We can replicate many typical process systems and you can test your product on a full range of Silverson high shear mixers.

Why leading manufacturers choose Silverson

Time after time, companies specify Silverson mixers as the “standard” equipment for their mixing process. A single Silverson high shear mixer can replace multiple pieces of conventional equipment, delivering faster, cleaner and more consistent results.

Ready to improve your product?

Contact the Silverson team today to discuss how high shear mixing can benefit your mixing process, or to arrange a trial.

IMAGES COURTESY OF Silverson Machines