The Icon Advantage

Setting the standard for precision, reliability and food safety in product inspection.

For more than 25 years, Fortress Technology Inc. has earned a global reputation for developing dependable, high-performance product inspection systems. From its Toronto headquarters, Fortress continues to push the boundaries of food safety, precision engineering and manufacturing efficiency.

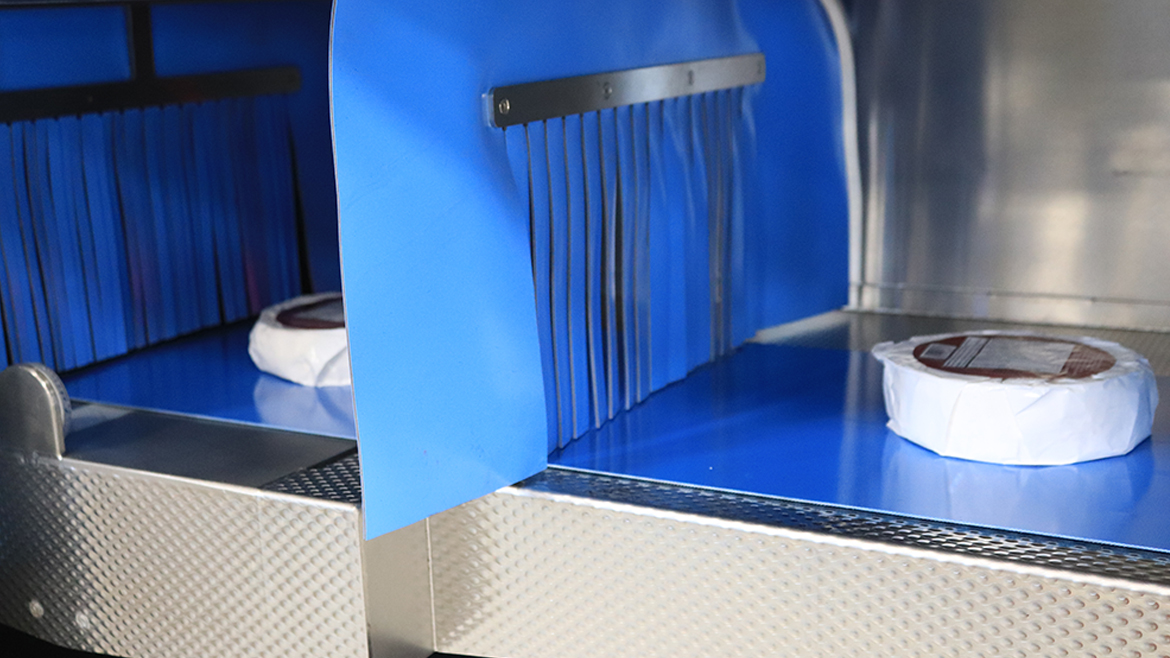

At the forefront of its inspection lineup is the Icon X-ray system – a high-accuracy solution engineered to help food manufacturers achieve exceptional quality control and contaminant detection.

Engineered for Precision and Safety

Purpose-built for high-care food production environments, the Icon X-ray is designed to detect and remove contaminants such as metal, glass, ceramic and dense plastics. Its integrated automatic reject mechanism ensures any suspect products are swiftly and safely removed from the line, all within a compact footprint that maximizes floor space.

Every Icon X-ray reflects Fortress’s core design philosophy: simple operation, outstanding reliability and exceptional performance. According to Steve Gidman, Founder and CEO of Fortress Technology, “The Icon X-ray represents years of continuous refinement and customer-driven innovation. It’s built to deliver precision and reliability in even the most demanding production settings.”

Performance that Drives Confidence

Sponsored by

Featuring IA+ detection technology, the Icon X-ray achieves outstanding sensitivity and consistency, even with complex products or packaging materials. The system’s food-grade construction includes sloped, hygienic surfaces for easy washdown, along with a maintenance-free generator and modular components that simplify cleaning and servicing.

To ensure safety from the start, the Icon incorporates full radiation shielding compliant with international standards – eliminating the need for post-installation modifications or retrofits.

Supporting Food Safety and Traceability

The Icon provides comprehensive auditing, reporting and traceability tools, allowing manufacturers to maintain clear documentation for compliance and quality assurance programs. These features give production teams greater visibility into their inspection data, making it easier to demonstrate compliance and track performance trends.

Integration and Flexibility

As part of Fortress’s expanding inspection platform, the Icon can be configured to include additional technologies such as metal detection, checkweighing or vision inspection — all within the same compact enclosure. This multi-technology approach reduces space requirements, streamlines data collection and simplifies overall equipment management.

The result: a durable, highly accurate, and future-ready inspection system that helps manufacturers safeguard product integrity, meet global food safety standards and protect brand reputation — all while optimizing production efficiency.

IMAGES COURTESY OF Tecnetics Industries, Inc.